Our Group organises 3000+ Global Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ ������ý Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

������ý Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

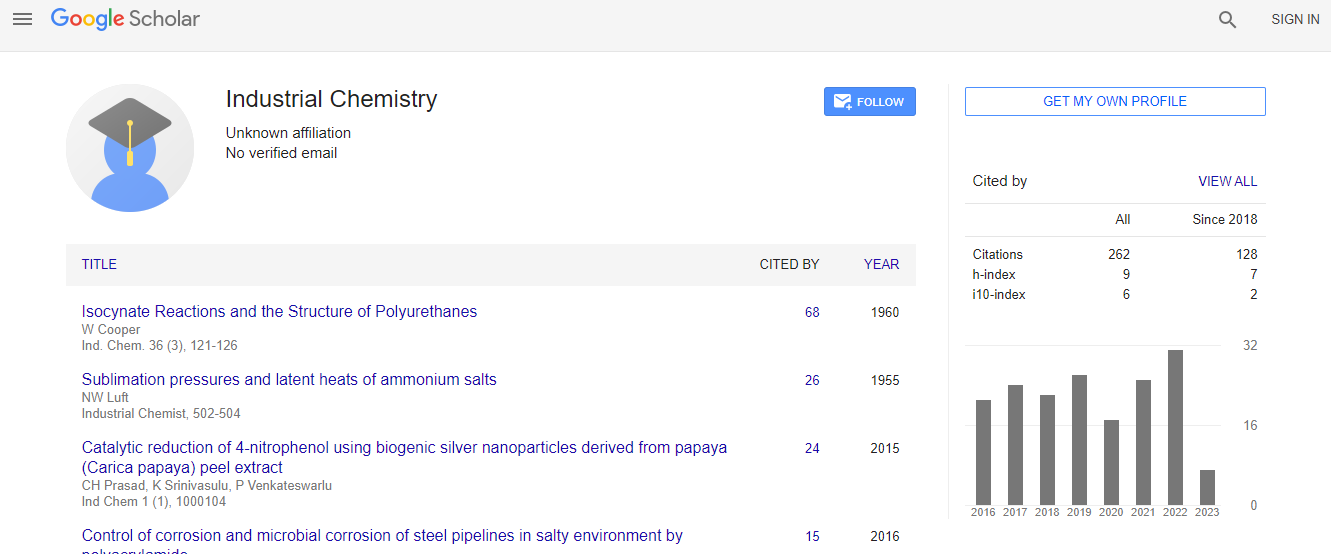

Citations : 262

Indexed In

- Index Copernicus

- Google Scholar

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Geneva Foundation for Medical Education and Research

- Euro Pub

Useful Links

Recommended Journals

Related Subjects

Share This Page

Novel Ni alloy-graphene composite electrodes for hydrogen production

International Conference on Industrial Chemistry

D Krishna Bhat

National Institute of Technology Karnataka, India

Posters & Accepted Abstracts: Ind Chem

DOI:

Abstract

Hydrogen, a renewable and clean fuel, is considered as a potential energy carrier for future energy infrastructure. The electrocatalytic splitting of water by hydrogen evolution reaction (HER) is an important process with high energy conversion efficiency for hydrogen production. Active, stable and cost-effective electrocatalysts are a key to water splitting for hydrogen production through electrolysis. Herein, we report the facile preparation of highly porous Ni alloy-Graphene composite electrode by embedding graphene into the Ni alloy matrix via room temperature electrodeposition for electrocatalytic applications such as water splitting. The incorporation of graphene into Ni alloy matrix enhances the catalyst��?s activity for HER in alkaline solution. The best coating exhibits a maximum current density of -850 mA cm-2 at -1.6 V, which is approximately 4 times better than that of binary Ni alloys indicating higher activity for hydrogen production. Addition of graphene to electrolyte bath results in porous encapsulated bundle of alloy nano-particles within the graphene network which effectively increases the elelctrochemically active surface area. As indicated by XPS analysis results, on addition of graphene metal content in the deposit increases and as a result both cobalt/cobalt oxide and nickel/nickel oxide sites are evenly distributed on Ni alloy- Graphene composite electrode surface which is responsible for increased HER activity. The Tafel slope analysis showed that the HER follows Volmer-Tafel mechanism. The structure-property relationship of Co-Ni-G composite coating has been discussed by interpreting field emission scanning electron microscopy (FESEM), X-ray photoelectron spectroscopy (XPS) and X-ray diffraction (XRD) analysis results.Biography

Email: denthajekb@gmail.com