Our Group organises 3000+ Global Events every year across USA, Europe & Asia with support from 1000 more scientific Societies and Publishes 700+ ������ý Access Journals which contains over 50000 eminent personalities, reputed scientists as editorial board members.

������ý Access Journals gaining more Readers and Citations

700 Journals and 15,000,000 Readers Each Journal is getting 25,000+ Readers

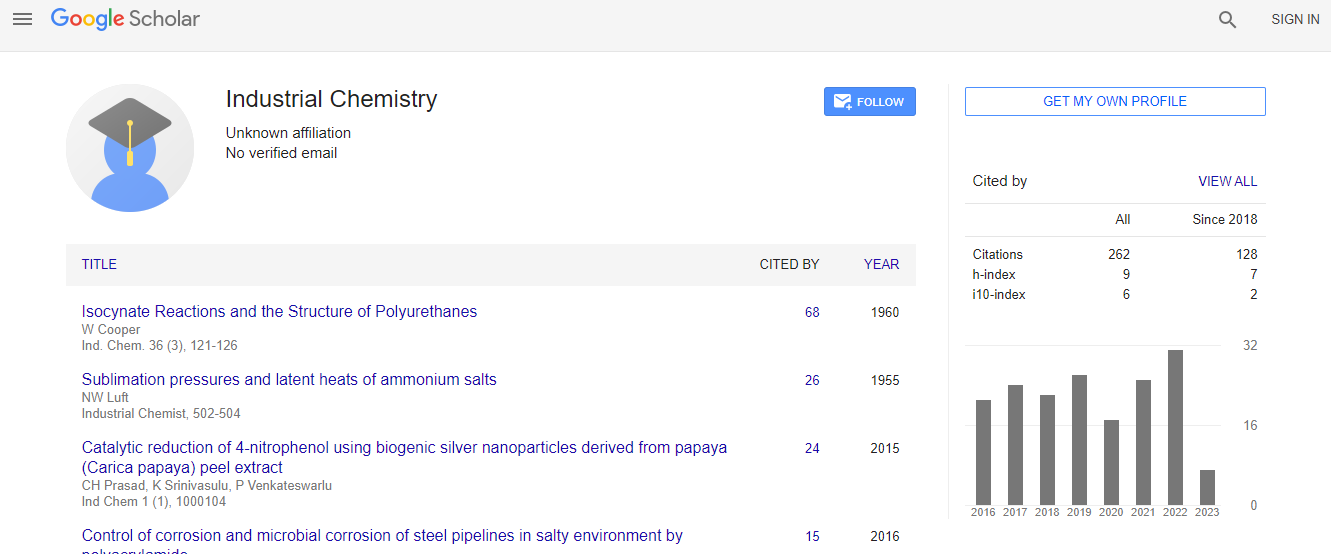

Citations : 262

Indexed In

- Index Copernicus

- Google Scholar

- RefSeek

- Directory of Research Journal Indexing (DRJI)

- Hamdard University

- EBSCO A-Z

- OCLC- WorldCat

- Scholarsteer

- Geneva Foundation for Medical Education and Research

- Euro Pub

Useful Links

Recommended Journals

Related Subjects

Share This Page

TMSR materials development: Carbide dispersed strengthening nickel based alloys

International Conference on Industrial Chemistry

Hefei Huang, Xiaoling Zhou, Chao Yang, Wei Zhang, Zhijun Li and Xingtai Zhou

Chinese Academy of Sciences, China

Posters & Accepted Abstracts: Ind Chem

DOI:

Abstract

The development of high-temperature irradiation-resistant nickel-based alloys has been receiving much attention due to their potential applications in molten salt reactors (MSRs). Silicon carbide nanoparticle-reinforced nickel-based composites (Ni-SiCNP), with milling time ranged from 8 to 48h, were prepared using mechanical alloying and spark plasma sintering. In addition, unreinforced pure nickel samples were also prepared for comparative purposes. The microstructure of the Niâ�?�?SiCNP composites was characterized by TEM and their mechanical properties were investigated by tensile measurements. The TEM results showed well-dispersed SiCNP particles, either within the matrix, between twins or along grain boundaries (GB), as well as the presence of stacking faults and twin structures, characteristics of materials with low stacking fault energy. The tensile test results indicated that the addition of SiCNP can effectively strengthen the nickel. Furthermore, the helium diffusion behavior of such composites and pure nickel under 3 MeV helium ion irradiation at 600�?°C with ion fluence up to 3�?�?1020 ions/m2 has also been studied. The TEM results indicated that the presence of dispersed SiCNP in nickel can inhibit the growth of helium bubbles, thereby mitigate the helium embrittlement and swelling of nickel-based alloys. The theoretical calculation results using the density functional theory (DFT) showed that the helium atoms prefer to diffuse to the interface between SiCNP and nickel matrix, and thus avoid the grain boundary segregation and also the growth of helium bubbles. This study confirmed the feasibility of dispersing carbides in nickel-based alloys to improve the irradiation-resistant performance of materials.Biography

Email: huanghefei@sinap.ac.cn